Vediamo un pò se riesco ad aiutarti.....

poi da DigitalCorvette.com

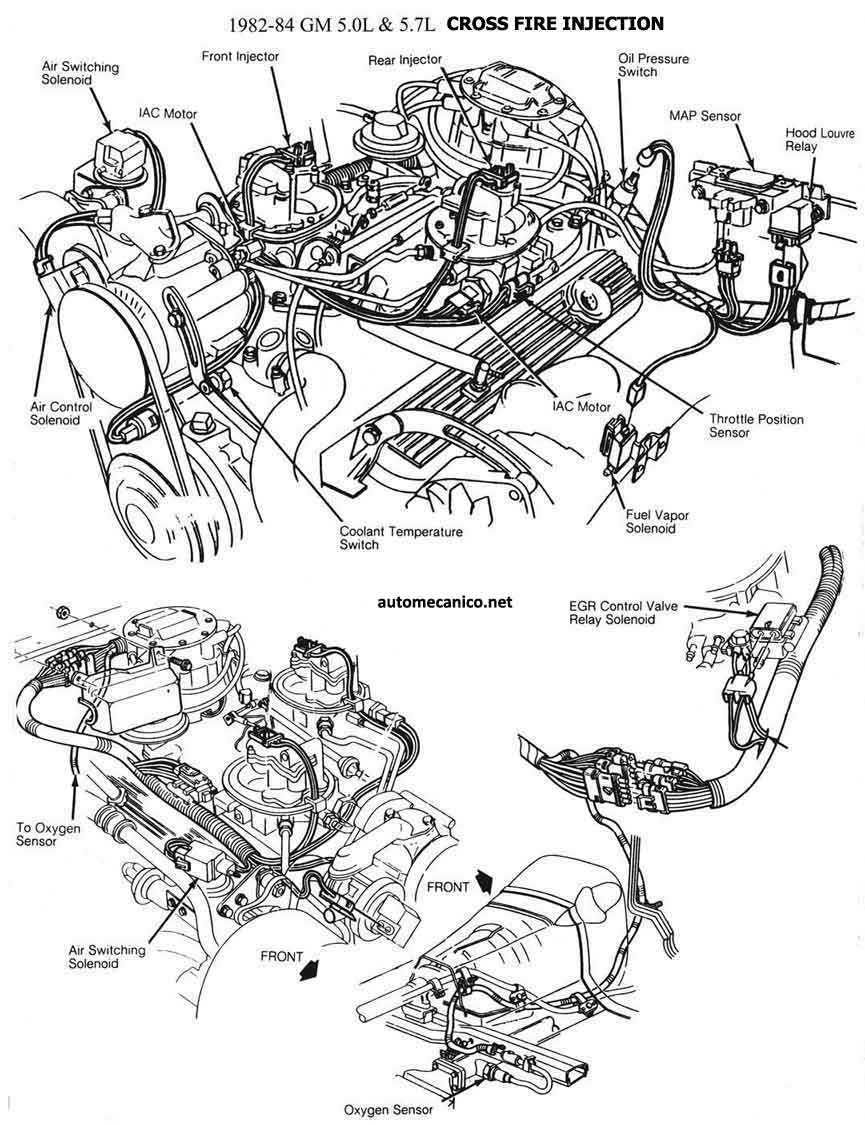

"there SIMULAR but not IDENTICALThe 1984 5.7L (VIN 8) engine is equipped with a Model 400 Throttle Body Injection (TBI) system, also referred to as the Cross-fire Injection system. This system consists of a pair of throttle body units which are mounted in front and rear positions on a single manifold. This arrangement lets each TBI unit supply the proper air/fuel mixture through a tuned crossover runner in the intake manifold to the bank of cylinders on the opposite side of the engine. This is the reason for the name "Crossfire injection". Each TBI unit feeds the cylinders on the opposite side. The front TBI gets the fuel from the fuel pump. The fuel then goes through a fuel pressure compensator, through a separate line to the rear TBI, then through the fuel pressure regulator then returns to the fuel tank.

Fig. 1: Cross-fire Fuel Injection fuel meter system schematic

Each TBI unit has its own fuel injector which are controlled individually by the ECM. Each TBI has its own IAC valve, which operate together. A throttle rod connects the throttle valves together. A single Throttle Position Sensor (TPS) is used on the rear TBI unit only. Also, a throttle bore tube is located under the manifold cover, below each throttle valve to help in mixture distribution. The throttle body portion of each TBI unit has several tubes which supply a manifold vacuum signal required for the operation of related engine and emission control systems. A vacuum port, located above the throttle valve is connected to the capped tubes used for on vehicle service air flow balancing, for final throttle valve synchronization. The amount of fuel delivered to the injectors is determined by an electronic signal supplied by the ECM. The TBI unit does not control, but is controlled by, the ECM. The ECM monitors several engine and vehicle conditions needed to calculate the fuel delivery time of the injectors. Delivery time may be modified by the ECM to reflect various operating conditions, such as cranking, cold starting, altitude, acceleration and deceleration. Each TBI unit has its own fuel injector which are controlled individually by the ECM.

Relieving Fuel System Pressure

CAUTION

Observe all applicable safety precautions when working around fuel. Whenever servicing the fuel system, always work in a well ventilated area. Do not allow fuel spray or vapors to come in contact with a spark or open flame. Keep a dry chemical fire extinguisher near the work area. Always keep fuel in a container specifically designed for fuel storage; also, always properly seal fuel containers to avoid the possibility of fire or explosion.

Place the transmission in PARK (automatic transmissions) or NEUTRAL (manual transmission), then set the parking brake and block the drive wheels.

Loosen the fuel filler cap to relieve tank pressure.

Remove the FUEL PUMP fuse from the fuse block in the passenger compartment.

Start the engine and allow to run until it stops due to lack of fuel.

Engage the starter (turn key to start) for three seconds to dissipate all pressure in the fuel lines.

Turn the ignition OFF, then re-engage the connector at the fuel tank or install the fuel pump fuse.

Disconnect the negative battery cable to prevent accidental fuel spillage should the ignition key accidentally be turned ON with a fuel fitting disconnected.

When fuel service is finished, tighten the fuel filler cap and connect the negative battery cable.

CAUTION

To reduce the chance of personal injury when disconnecting a fuel line, always cover the fuel line with cloth to collect escaping fuel, then place the cloth in an approved container for disposal."

Non ho la traduzione ma come vedi è facile

Rispondi Citando

Rispondi Citando

) che le iniezioni di carburante sono impulsive e regolate dalla centralina (ecm). Mi ricorda moltissimo il principio di un impianto gpl/metano sequenziale.

) che le iniezioni di carburante sono impulsive e regolate dalla centralina (ecm). Mi ricorda moltissimo il principio di un impianto gpl/metano sequenziale. :

: